Hydraulic tamper stroke adjustment

A correctly set tamper stroke is a key factor in both compaction result and the floating behaviour of screeds.

As it is very time-consuming to adjust the tamper stroke mechanically, it is often not adjusted at all, which means that different layer thicknesses are frequently paved at the same setting. VÖGELE developed the hydraulic tamper stroke adjustment system to stop this happening. The Dual Power Shift Tamper enables paver operators to set the ideal tamper stroke for the paving task in question quite simply at the touch of a button.

It is very time-consuming to adjust the tamper stroke mechanically because the eccentric bolts on every bearing have to be adjusted manually. As an example: for a pave width of 12 m, 16 eccentric bolts need to be adjusted. Assuming 8 to 10 minutes per bearing, this means the whole process takes over 2 hours. The consequence is that the tamper stroke is often not adjusted at all if mechanical adjustment is required.

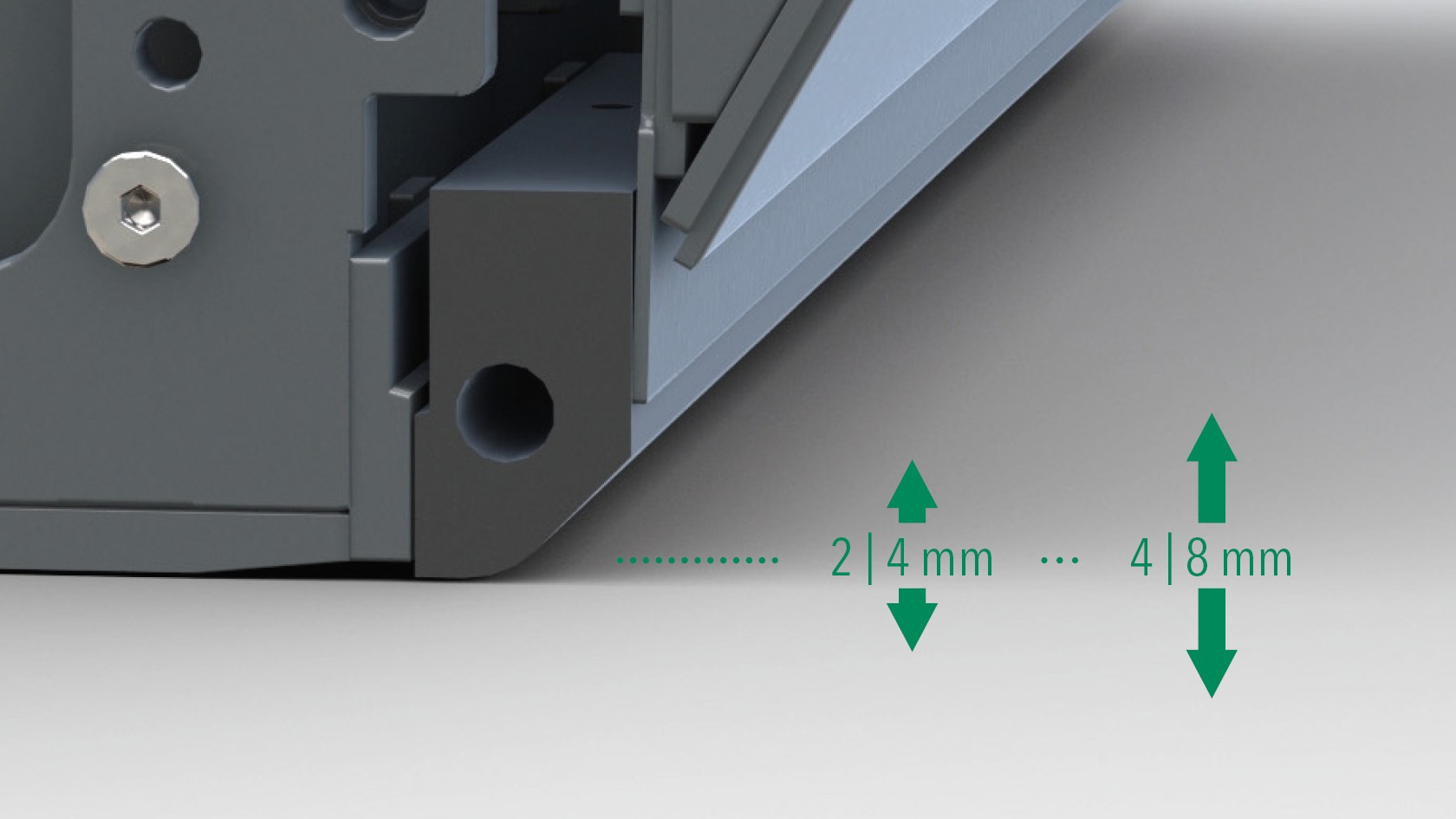

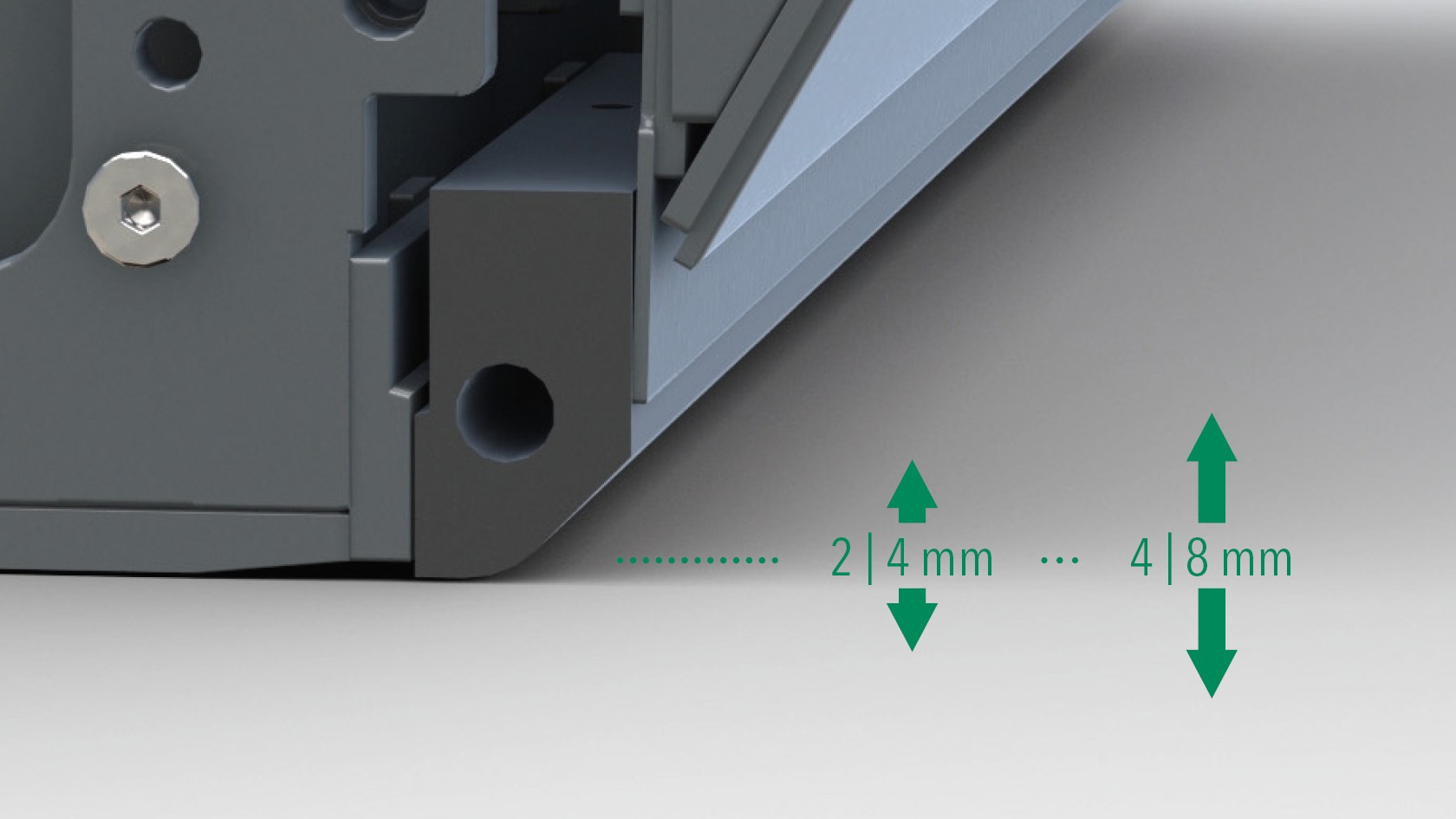

The technology behind hydraulic tamper stroke adjustment is perfectly simple: altering the direction of rotation of the eccentric tamper shaft adjusts tamper stroke. Depending on configuration, this is either 2 and 4 mm or 4 and 8 mm. High-quality paving results can consequently be achieved much more conveniently, and an enormous amount of time saved compared to mechanical adjustment.

Hydraulic tamper stroke adjustment is available for the following latest-generation extending screeds and and for the following fixed-width screeds SB 300 and SB 350.

Fixed-width screed

| Compacting systems | TV, TP1, TP2 |

| Pave width | 3.00 m - 16.00 m |

| Basic width | 3 m |

Fixed-width screed

| Compacting systems | TV, TP1, TP2 |

| Pave width | 3.50 m - 18.00 m |

| Basic width | 3.5 m |